We're cutting the seats on these panheads for my 84" stroker project. The combustion chambers look like someone filled 'em with salt water and let them sit for years. They surfaced nice, the seats are solid, spigots all good - I'm runnin' 'em !

Kevin's 1955 KH oil pump is a one-or-two-year-only pump. You need all the correct parts to make it work - so I came up with all the correct parts ! The breather is timed, oil pump and pinion gears installed correctly.

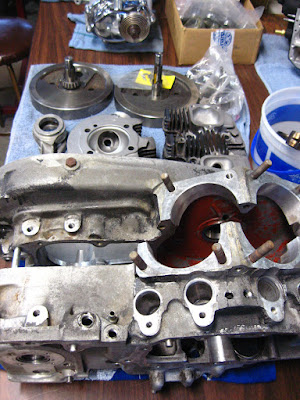

I got these cases disassembled (for Ricky at Anchor Moto). His plan is to cut the transmission portion of the cases off - and run a 4 speed big twin tranny. I'll do the lower end (what's left of it).

Last night, I bored these cylinders for my friend Eric from Portland. It's another 1966 XLCH motor, and he wants to keep it "all krusty lookin" to match the rest of it's barn-find, old school chopper chassis. No paint, no polish - just wash and assemble - leave the patina. We'll use these +.010 NOS H-D pistons . . .

Eric's cases all washed and dry, carbon blasted off the heads, one new flywheel, new forked rod, races honed, all other crucial dimensions being checked and sized. Time to quit for the night, go home . . . and relax on the couch.

2 comments:

Ricky, Are you turning the seat cutter with a motor?

Just curious......

No, by hand. The Neway has a nice spring loaded deal that gives even down-ward pressure with the carbide cutters(which are adjustable) so you cut where you want on the seat. You can feel it cutting, and then I let up lightly at the end to give the smoothest surface I can before lapping it in. They make a Harley Kit, but you can just buy what you want(I didn't need the Evo stuff) and get a variety of pilots and away you go.

Post a Comment