Me and my dad (Big Noot / The Original Noot ) work together on these motors. Even after all these years, we still learn new stuff. Last night it was snowin' and blowin' like crazy, but we were nice and warm in the shop . . . and it was one of those work nights where everything went perfect !

I got my friend Josh's connecting rods all Sunnen honed for fitment of +.001 rollers (that I bought NOS H-D in the box). This tool is handy to get the flywheels "in the ball-park" before the truing stand. They trued up about as perfect as they could get. The Last Word indicator needle had barely a flicker on each shaft. Sweet !

Kevin's KH is about done. Noot installed a new adjuster shoe, we like to use the original H-D lock tools to secure the primary when tightening the nuts. A heavy air-impact has a tendency to pull the threads, squash tapers and gall the nuts. This way it's serviceable "in-the-pits" if needed. You can see the factory lock tool in the center, and the heavy steel tool locking the hub to the basket. OEM tools he bought back in the 60s ! This KH runs a 30T engine sprocket to get the revs up quick and requires a shorter primary chain.

These pan cases have been welded, machined, heli-coiled and sealed. I'll set up some mics and bore gauges - then start measuring shafts and races - line lapping comes next. (dirty job)

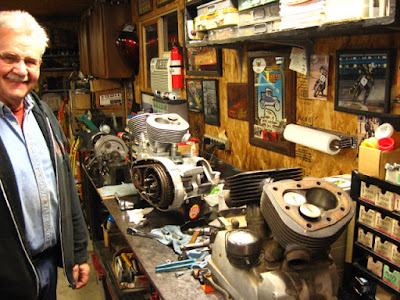

Here we're trying to figure out if this barn find K-Model engine (near photo) has hot cams in it without removing the gear cover. We're comparing valve lift to Kevin's hotrod KH motor. I don't think it does . . . rats. It looks like a K factory here today. What else we got to do ????

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment